ESD causes up to 33% of electronics to fail.

ESD makes more than one-third of semiconductor failures happen.

ESD can cause 8% to 33% of product loss in factories.

Foil does not keep electronics safe from static electricity. It can even make damage more likely.

Use anti-static bags made for electronics. These bags stop static from building up and keep parts safe.

Always be careful when you touch electronics. Use grounding tools and keep items in a cool, dry place to stop static damage.

You might ask what "anti-static" means. In material science, anti-static is about stopping static electricity from building up. These materials let electric charges move across their surface. This way, static does not gather and cause trouble. Here is a table with some important words:

Term | Definition |

|---|---|

Antistatic Agent | Compounds that help surfaces not collect static charges by making them conduct electricity better. |

Function | Gets rid of static charges on materials so there is no sparking or dust sticking. |

Mechanism | Pulls in moisture to make a water layer that helps charges move away. |

You can sort materials by how they deal with electricity:

Material Type | Description |

|---|---|

Anti-static Material | Stops static electricity from building up and can be conductive or dissipative. |

Insulative Material | Blocks electric charges but does not stop static from building up. |

Materials are put into groups by their surface resistivity. For example:

Classification | Surface Resistivity (Ω/square) |

|---|---|

Shielding | Less than 10³ |

Conductive | Less than 10⁴ |

Dissipative | Between 10⁴ and 10¹¹ |

Insulative | More than 10¹¹ |

You need anti-static protection when working with electronics. Static electricity can build up on your body or things around you. If you touch a sensitive part, static can jump and break it. Even a tiny shock, like 100 volts, can hurt a chip or circuit.

If you do not have enough protection, small parts can get ruined by ESD. This damage can cost a lot of money. Even small shocks can hurt parts and make them fail later.

Using anti-static materials helps keep your devices safe. This keeps your electronics working longer and saves money. You also avoid losing data or having weird problems. In factories or labs, anti-static solutions help everything work well and safely.

Some people think aluminum foil can keep electronics safe from electrostatic discharge. Regular foil is a conductive material. But it does not stop static from building up. You need special static-dissipative coatings for real esd packaging. Multi-layer antistatic films have these coatings to control static. These coatings help charges move away safely. The foil itself only blocks electromagnetic waves.

Here is a simple look at different esd packaging choices:

Material Type | Structure & Function |

|---|---|

Ordinary Aluminum Foil | Conductive material, blocks EMI, does not prevent static buildup or electrostatic discharge |

Layers of foil and static-dissipative polymers, provide EMI shielding and static control | |

Standard Antistatic Bags (Pink PE) | Static-dissipative plastics, prevent static buildup, less EMI shielding than foil-based composites |

You can see that only static-dissipative layers make esd packaging safe for sensitive electronics.

Aluminum foil has much lower surface resistivity than static-dissipative materials.

Static-dissipative coatings have resistivity between 10⁸ and 10¹¹ ohms, with charge decay times under 0.5 seconds.

Using plain foil for esd packaging increases the risk of electrostatic discharge.

If you use aluminum foil instead of antistatic bags, there are risks from electrostatic discharge (ESD). Aluminum foil can work as a Faraday cage to block ESD. But if you do not handle it right, it can cause a difference in charge. This may hurt sensitive electronic parts.

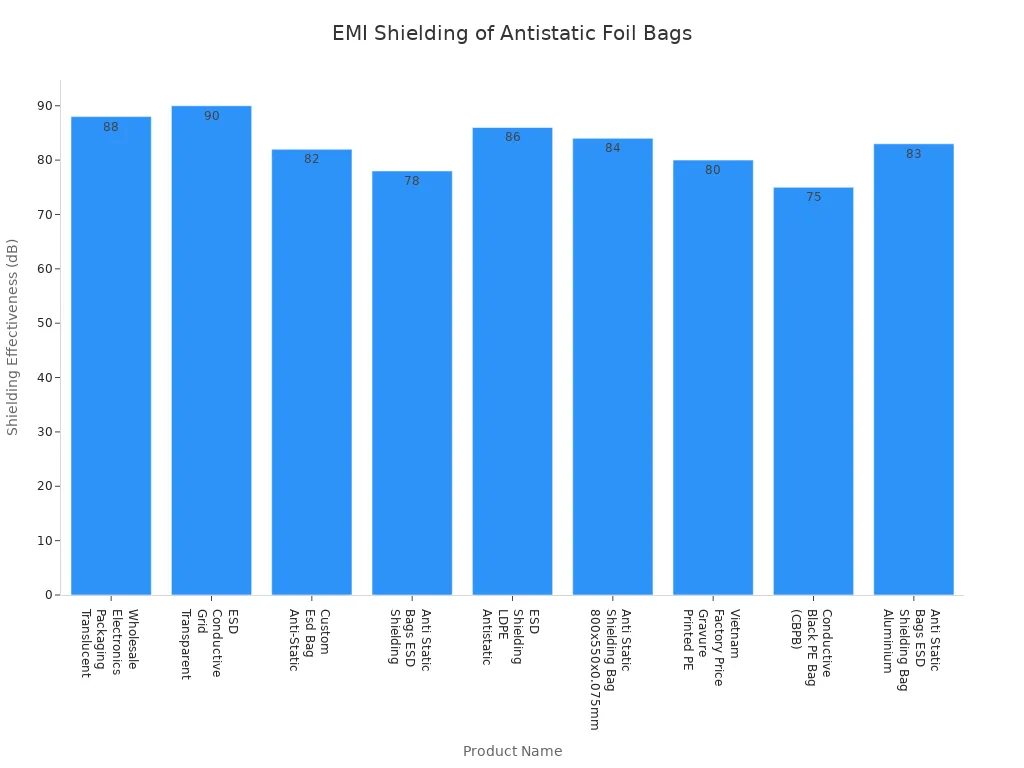

Aluminum foil in multi-layer esd packaging works like a Faraday cage. This keeps outside electromagnetic fields away. How well it works depends on the material and how tightly you seal the package. Multi-layer antistatic foil bags can block a lot of EMI:

Product Name | Shielding Effectiveness (dB) |

|---|---|

Anti Static Shielding Bag ESD Metalized Shield Bag | 85+ |

Wholesale Electronics Packaging Translucent ESD protection | 88 |

ESD Conductive Grid Transparent Durable Antistatic Shielding | 90 |

Custom Esd Bag Anti-Static Transparency | 82 |

Anti Static Bags ESD Shielding | 78 |

ESD Shielding LDPE Antistatic Bags | 86 |

Anti Static Shielding Bag 800x550x0.075mm | 84 |

Vietnam Factory Price Gravure Printed PE Laminated | 80 |

Conductive Black PE Bag (CBPB) | 75 |

Anti Static Bags ESD Shielding Bag Aluminium Bags | 83 |

You need both static-dissipative coatings and the Faraday cage effect to fully protect electronics from electrostatic discharge.

An antistatic bag is special packaging for electronics. It helps protect them from static electricity. These bags use different materials to control static. They also shield sensitive parts. The table below shows the main types of antistatic bags and what they are made of:

Type of Bag | Material Description |

|---|---|

Pink Antistatic Bag | Made from polyethylene film with antistatic agents added. |

Black Conductive Bag | Made from carbon-filled polyethylene. It gives better conductivity and shielding than pink bags. |

Metalized ESD Bags | Made of polyethylene with a metalized foil layer. This gives strong shielding against ESD and EMI. |

Static Shielding Bags | Built with many layers. They have an inner static-dissipative layer and an outer metalized layer. |

Anti-static aluminum foil bags and anti-static shielding bags use layers. These layers block static and electromagnetic interference.

When you look at anti-static foil bags and regular antistatic bags, you see some big differences. Anti-static aluminum foil bags have many layers. They protect against static, moisture, and light. Regular antistatic bags, like pink PE bags, only stop static inside the bag. They do not block outside static or light.

Anti-static aluminum foil bags keep out moisture, light, and static.

Regular antistatic bags give basic static protection but not much shielding.

The many layers in anti-static shielding bags make them safer for electronics.

Feature | Foil-Based Composite Bags | Standard Antistatic Bags |

|---|---|---|

Protection Against Moisture | Yes | Limited |

Protection Against Light | Yes | No |

Protection Against Static | Yes (internal and external) | Basic (internal only) |

Multilayer Construction | Yes (enhances protection) | No |

Faraday Cage Effect | Yes | No |

You should pick anti-static aluminum foil bags or anti-static shielding bags for items that are sensitive to static. These bags give the best protection and meet strict rules like ANSI/ESD S20.20 and IEC 61340.

You can keep electronics safe by following these tips:

Always use anti-static shielding bags or anti-static aluminum foil bags for static-sensitive parts.

Store aluminum foil bags in a dry, cool place. Keep the humidity between 40% and 60%.

Do not touch the inside of the bag. This helps stop static from building up.

Check bags often for damage. Replace them if you see any problems.

Use grounding tools like wrist straps and anti-static mats when you handle electronics.

Keep your workspace clean and dry. This helps protect the aluminum foil bag.

The right anti-static shielding bag or anti-static aluminum foil bag can stop expensive damage. Good storage and careful handling keep your electronics safe from static.

You should not use aluminum foil to protect from ESD. Foil does not block static. It can damage electronics. Many people believe foil is safe. This is not true. Here are some mistakes people make:

Misconception | Reality |

|---|---|

Foil protects against ESD | Foil lets electricity move and can hurt devices. |

Wrapping PCBs in foil is safe | Experts say you should not do this. |

Pick anti-static bags to store electronics safely. Always use ESD safety steps.

Regular foil is not good for stopping static. It does not keep static from building up. Using foil can make your electronics get damaged.

A real anti-static bag has special layers or coatings. These help move static charges away. They keep the parts inside safe.

Put items in anti-static bags.

Store them in a cool, dry spot.

Do not touch electronic parts with your bare hands.

Quick Links

Support

Contact Us