Views: 0 Author: Site Editor Publish Time: 2025-09-09 Origin: Site

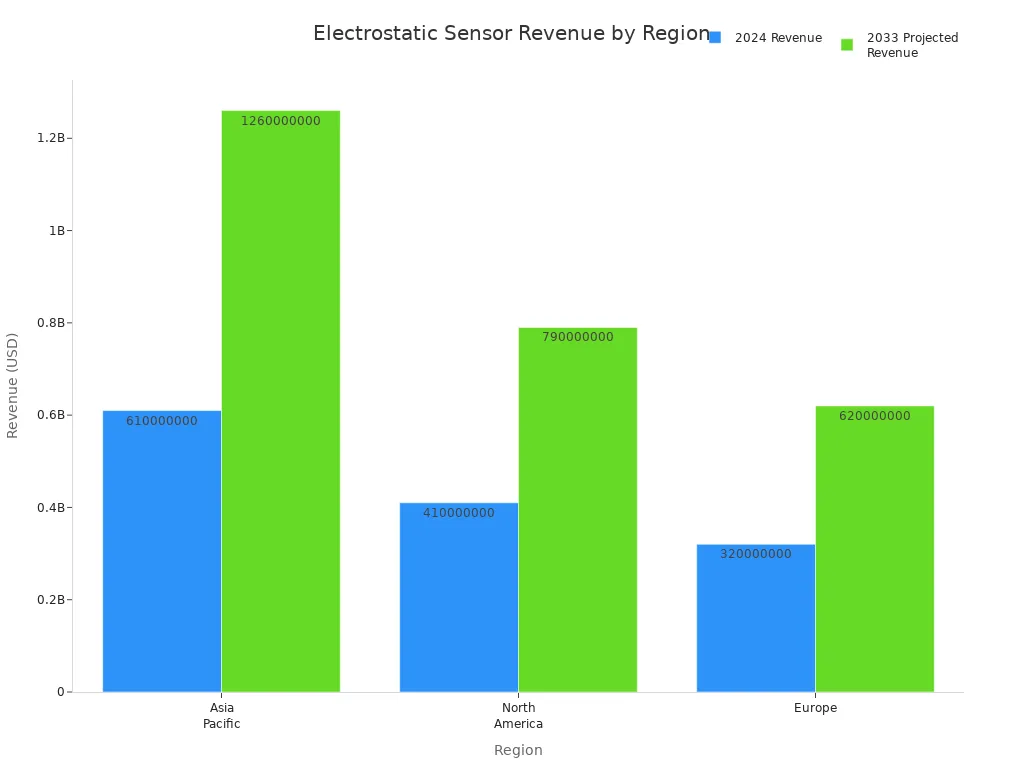

Region | Revenue in 2024 (USD) | Projected Revenue by 2033 (USD) | CAGR (%) |

|---|---|---|---|

Asia Pacific | 610 million | 1.26 billion | 9.2 |

North America | 410 million | 790 million | N/A |

Europe | 320 million | 620 million | N/A |

Electrostatic sensors find static electricity and help control it. This keeps work areas safe and clean.

These sensors use triboelectric nanogenerators to work without batteries. This makes them good for the environment and saves energy.

When you use electrostatic sensors with static eliminators, static is controlled better. This keeps equipment safe and helps make better products.

Finding static problems early can save money and stop work delays in factories.

In the future, electrostatic sensors will get better at saving energy and using smart technology. This will make work safer and more efficient.

Electrostatic sensors help you find and measure static electricity. They use electrostatic induction to work. When something with a charge gets close, the sensor notices the movement of charges inside. This makes a current that you can measure. The sensor shows you data right away, so you see when static changes. These sensors are very accurate because they adjust for distance and check humidity. This helps you control static better.

Tip: Electrostatic sensors let you find static problems early, before they hurt your equipment or products.

Electrostatic sensors watch static charge on surfaces all the time. You can use them to check for static on machines, tables, or packages. These sensors help you see changes in static and act fast. Some sensors, like the ZJ-SD model, can measure movement and speed very well. They also work with different sizes of workpieces, so you get good results every time.

Mechanism | Description |

|---|---|

Show where charge is on surfaces and find wear spots. | |

Contact Potential Difference (CPD) | Show how charge changes when things wear down. |

Charge Distribution Measurement | Connect surface charge to chemistry, showing machine damage. |

You can use electrostatic sensors with static eliminators like ion fans and ion bars. This makes a system that controls static. The sensor finds static, and the eliminator gets rid of it. These sensors and eliminators work together to keep your area safe and clean. Ionizers take away dust and balance static. Some ionizers work without air, so they protect delicate electronics.

Benefit Description | Details |

|---|---|

Neutralization of Static Charge | Ionizers use positive and negative ions to remove static charge. |

Dust Removal | Ionizers stop dust from sticking after static is gone. |

Airless Operation | Ionizers without blowers keep sensitive parts safe from dust and wind. |

Electrostatic sensors help you keep production lines safe and high quality. These sensors let you find static before it causes problems or breaks equipment. If you catch issues early, you save money and keep things working well.

Electrostatic sensors are important in printing, coating, and packaging. You use them to watch static and stop dust or dirt from ruining products. These sensors help make sure your products are good.

You keep electronics safe by using electrostatic sensors and anti-static tools. You store parts in special boxes, wear ESD wrist straps, and ground your tables. These sensors help you stop electrostatic discharge, which can break expensive parts.

Electrostatic sensors warn you about problems early. You can fix things before equipment breaks or data is lost. These sensors help keep workers safe and your business running well.

Note: GD Decent Industry Co., Ltd. has many electrostatic sensors, ion fans, and anti-static materials. You can trust their products to keep your space clean and protect your important items.

You see the triboelectric effect almost every day. You might not always notice it. When you rub a balloon on your hair, it can stick to a wall. This happens because of triboelectricity. The effect starts when two different things touch and then pull apart. Electrons move from one thing to the other. This movement makes an electric charge.

The triboelectric effect is the base for many new sensors.

Triboelectric nanogenerators use this effect to make electricity from movement.

You can find triboelectric nanogenerators in sensors that power themselves. These sensors get energy from shaking, tapping, or walking.

Triboelectric sensors help collect energy from vibrations and body movements.

Many companies use triboelectric sensors for tidal energy, wearable gadgets, and bendable electronics.

Triboelectricity lets people build sensors that do not need batteries. These sensors work in lots of places, like factories or even in your clothes.

The first triboelectric sensors helped measure static charges. But they had some problems. You needed special materials to make them work well. This made building them harder and less flexible. You also had to know how to program to use them with things like Arduino.

Material | Charge Generation Properties |

|---|---|

PTFE | High surface charge density |

PDMS | Variable charge density based on processing |

FEP | Effective in energy harvesting |

PET | Good triboelectric properties |

Graphene | Enhanced charge generation capabilities |

Each material gives different triboelectric properties. PTFE and FEP are good for making energy. Graphene is even better at making charges. Early triboelectric sensors needed these materials to work and measure static charges.

Early triboelectric sensors were hard to make.

You had to use certain materials, so you had fewer choices.

It was tough to connect them to common platforms because you needed programming skills.

Now, triboelectric sensors are much better. You can use them in more ways because materials and connections have improved.

Triboelectric nanogenerators are changing how factories use sensors. They use the triboelectric effect to turn movement into electricity. When two things touch and pull apart, they make a charge. This charge can power sensors that do not need batteries. These sensors work for a long time without stopping.

Triboelectric nanogenerators work well when things move slowly. They can collect energy from ocean waves, machines, or even footsteps. New designs help them catch more energy. Better circuits help them change energy more easily. This means you get more power and better energy use.

Triboelectric nanogenerators use special tracking to get more power.

You can use them to collect energy where batteries do not work.

They are better than old electromagnetic generators at catching odd movements.

You can use them in sensors that watch how things move.

They help you measure shaking and movement in buildings.

You can use them in smart factories and wearable gadgets.

They let sensors work without wires or batteries.

You can use them in hybrid sensor designs for better results.

They help sensors last longer and need less fixing.

You can use them to measure movement in machines and buildings.

They make it easier to collect energy in factories.

They work with materials like PTFE, FEP, and graphene to sense better.

They let you make sensors that power themselves for many uses.

Tip: Triboelectric nanogenerators can power sensors where you cannot use wires or change batteries.

Energy harvesting lets you collect power from your surroundings. You can use shaking, moving, or pressure changes to run sensors. This helps you make sensors that work for years without new batteries.

Factories use different ways to collect energy. Piezoelectric, electromagnetic, and electrostatic methods all help. Each way has good points and some limits.

Energy Harvesting Method | Principle | Advantages | Limitations |

|---|---|---|---|

Piezoelectric | Direct piezoelectric effect | Small, works well with fast movement | Power depends on the material |

Electromagnetic | Faraday’s law of induction | Strong, gives more power at slow movement | Bigger and harder to build |

Electrostatic | Changes in capacitance | Light, good for slow movement | Needs outside voltage to start |

You can use energy harvesting to power sensors on factory lines. Electrostatic energy harvesting uses moving plates to get energy from shaking. Circuits help make the energy ready for sensors.

Component | Description |

|---|---|

Electrostatic EH | Turns shaking into power for sensors. |

Parallel Plate Capacitor | Has one still plate and one moving plate to get energy. |

Resonator | Catches shaking energy well. |

Variable Capacitor | Changes how much energy it can hold to work better. |

Conditioning Circuit | Gets the energy ready for the sensor to use. |

You can use energy harvesting to make sensors for clean rooms, packing lines, and electronics factories. GD Decent Industry Co., Ltd.'s sensors use this technology to keep your work area safe. You get steady work and less time fixing things.

Note: Energy harvesting lets you use sensors where power is hard to get. You save money and make less waste.

Signal processing helps you get clear data from your sensors. Circuits filter out noise and make weak signals stronger. You can connect sensors to smart systems for better watching.

Self-powered sensors send data to computers and IoT systems. You get alerts right away when static changes. IoT helps you watch humidity and temperature. You can stop static discharge and protect your machines.

IoT sensors help you watch your workspace and keep it safe.

Sensors help you find problems early and fix them fast.

You get better machine care and less downtime.

Sensors send alerts to your phone or computer so you can act quickly.

GD Decent Industry Co., Ltd. has sensors with smart signal processing. You get good sensing and easy use with smart systems. You can use these sensors for building checks, packing, and making electronics.

Tip: Connect your sensors to IoT for better control and safety in your factory.

Electrostatic sensors are used in many industries now. These sensors help keep electronics, printing, and packaging lines safe. They stop dust and static from hurting products. In factories, sensors measure flow and check for moisture. They help find problems before machines stop working.

Here is a table that shows how sensors are used in different jobs:

Application | Study Reference |

|---|---|

Flow process analysis in pipelines | Wang, C., Zhang, J., Gao, W., Ding, H. & Wu, W. (2015). Cross-correlation focus method with an electrostatic sensor array for local particle velocity measurement in dilute gas-solid two-phase flow. Meas. Sci. Technol. 26, 115301. |

Flow characteristics study | Wen, Z., Ma, X. & Zuo, H. (2014). Characteristics analysis and experiment verification of electrostatic sensor for aero-engine exhaust gas monitoring. Meas. J. Int. Meas. Confed. 47, 633–644. |

Concentration profile mapping | Tang, X., Chen, Z., Li, Y. & Yang, Y. (2018). Compressive sensing-based electrostatic sensor array signal processing and exhausted abnormal debris detecting. Mech. Syst. Signal. Process. 105, 404–426. |

Mass flow rate measurement | Qian, X., Yan, Y., Huang, X. & Hu, Y. (2017). Measurement of the mass flow and velocity distributions of pulverized fuel in primary air pipes using electrostatic sensing techniques. IEEE Trans. Instrum. Meas. 66, 944–952. |

Moisture content estimation | Zhang, W., Cheng, X., Hu, Y. & Yan, Y. (2018). Measurement of moisture content in a fluidized bed dryer using an electrostatic sensor array. Powder Technol. 325, 49–57. |

Average particle size determination | Tajdari, T., Rahmat, M. F. & Wahab, N. A. (2014). New technique to measure particle size using electrostatic sensor. J. Electrostat. 72, 120–128. |

Triboelectric nanogenerators power sensors where wires or batteries do not work. These nanogenerators get energy from movement, like shaking or tapping. You can use them for traffic management and smart city projects. They also work in places with no dust. GD Decent Industry Co., Ltd. has special labels that resist heat and static. These labels help you track products and keep parts safe.

Tip: Using electrostatic sensors and triboelectric technology helps you make better products and have fewer warranty problems.

Triboelectric sensors are used in healthcare to watch your health. They help track blood pressure and blood oxygen. You can wear these sensors on your body. They send information to your phone or computer. This makes it easy to check your health at home or in the hospital.

Triboelectric sensors also help watch the environment. You can use them to check air quality and dust. Hospitals and labs use these sensors to keep rooms clean. They are used in traffic management to count cars and check roads. Smart city planners use these sensors to make cities safer.

Here are ways triboelectric sensors help in health and the environment:

You use wearable sensors to watch human health.

You use sensors to check clean rooms and hospitals.

You use sensors for traffic management in smart cities.

You use sensors to check food quality and shelf life.

You use sensors to keep food packaging clean.

Note: Electrostatic sensors and triboelectric technology help save money and give good solutions for health and the environment.

There are some problems when using electrostatic sensors and triboelectric technology. You need special floors and chairs in hospitals and labs. This stops static from building up. You must ground all equipment to stop static discharge. You also need to control humidity and use materials that make less static.

Here is a table that shows common problems:

Challenge Type | Description |

|---|---|

Static Control Flooring | You need floors that remove static in operating rooms and labs. |

Equipment Grounding | You must ground all medical and electronic equipment to stop ESD. |

Low-Charging Materials | You use materials that make less static to lower risks. |

Ionization | You use ionizers to remove static from air and surfaces in surgery rooms. |

Humidity Control | You keep humidity at the right level to stop static. |

Static Control Seating | You use special chairs to stop static in computer work areas. |

Other problems can make things harder:

It costs a lot to start using these sensors.

Small businesses may not know about these sensors.

Some places have hard rules to follow.

Problems in the supply chain can make sensors hard to get.

Making sensors needs raw materials.

Electrostatic sensors will be used even more in the future. New technology and automation help you use sensors in more places. You will see them in traffic management and smart city projects. They will also be used for health monitoring. Companies will make sensors smarter by connecting them to AI and IoT. This will help you get better and faster information.

Triboelectric nanogenerators and energy harvesting will help sensors last longer. You will use them in wearable devices for health. They will also help with environmental and traffic monitoring. These changes will make spaces safer and cleaner.

Callout: GD Decent Industry Co., Ltd. gives you advanced sensors and triboelectric solutions for the future. Their labels help you control static and meet industry rules.

You have watched electrostatic sensors change a lot over time. They started as simple triboelectric devices. Now, they are advanced tools for precision work. These sensors help you keep your workspace safe and efficient. Smart sensors let you check equipment from far away. You can use real-time data to fix things faster. You can find problems early and stop failures.

You keep workers safer by watching from a distance.

You make work better with fast data.

You stop accidents by finding problems early.

Soon, you will see big changes in energy harvesting and smart sensing. The table below shows what is coming:

Aspect | Details |

|---|---|

Market Growth | Energy harvesting systems will get bigger all over the world. |

Key Drivers | More IoT devices and wireless sensors will make people want more sensors. |

Technological Advancements | New materials and better ways to change energy will make sensors better. |

Applications | Sensors will power things far away, wearable gadgets, and smart buildings. |

Future Opportunities | Wearable technology and self-driving systems will bring new uses. |

Hybrid Systems | Mixing energy sources will help sensors work even better. |

GD Decent Industry Co., Ltd. is a leader with new sensor ideas. You will see more new things that make your work safer and smarter.

An electrostatic sensor helps you find static electricity. It can show you where static problems start. You can fix issues before things break. This keeps your workspace safe and your equipment working.

You put sensors close to machines or work tables. The sensors check for static all the time. If they spot a problem, you can fix it quickly. This stops delays and keeps products safe.

Yes! You can link sensors to ion fans or ion bars. The sensor finds static. The eliminator takes it away. Working together, they keep your area clean and safe.

Triboelectricity helps sensors make their own power. They get energy from movement, like shaking or tapping. You do not need wires or batteries for these sensors.

You can use GD Decent’s Electrostatic Sensor in electronics, printing, packaging, and clean rooms. The sensor helps you control static and protect sensitive parts. It keeps your production line working well.