Views: 0 Author: Site Editor Publish Time: 2025-09-09 Origin: Site

Product recalls and warranty claims often happen because of hidden static problems.

In electronics factories, companies lose about 6.5% of money each year from ESD events.

The electrostatic sensor from GD Decent Industry Co., Ltd. helps you find and control static right away. If you use sensors with ion fans, you can get rid of static fast. This keeps your work safe and running well.

Feature/Functionality | Description |

|---|---|

Role of Ion Fans | Get rid of unwanted static charges with ionized air |

Importance in Manufacturing | Protect fragile electronics and keep good quality |

Integration with Sensors | Allow real-time checks and quick static control |

Static electricity can hurt things made in factories. Electrostatic sensors help find static and stop it before it causes problems.

Ion fans work well with electrostatic sensors. They remove static charges fast. This keeps your workspace safe and helps you work better.

You need to take care of ionization systems often. Clean emitter points so ions stay strong and control static well.

Make a plan to control static. Look for places where static builds up. Put in dissipaters and check them often. This helps stop work delays.

Use rules like ANSI/ESD S20.20 to make things safer and better. This stops ESD problems and keeps electronics safe.

It is important to know when static charge builds up. The electrostatic sensor from GD Decent Industry Co., Ltd. helps you watch static levels as they change. This sensor uses different ways to find static charge fast and correctly.

Mechanism | Description |

|---|---|

Electrostatic Induction | The sensor notices changes in the electrostatic field from nearby charges. It makes an opposite charge on its surface. |

Movement of Mobile Charges | Charges inside the sensor move when they feel an outside charge. This movement makes a current. |

Current Flow Generation | The sensor measures and handles the current made by moving charges. |

You can see the results right away. This helps you act quickly if static charge could hurt your products. The sensor works with ionization systems to keep your workspace safe.

When you find static charge, you need to get rid of it fast. Ion fans use ionization to send ions into the air. These ions help remove static charge from surfaces.

Air ions are tiny groups that can get rid of static charge, even when materials do not let electricity flow well.

Positive ions move away from charged surfaces. Negative ions stick to these surfaces and lower the charge.

The speed of ions depends on how strong the electric field is. Scientists use the equation v = k ∙ E to show this movement.

You get the best results when you have the same amount of positive and negative ions. The electrostatic sensor gives information to the ion fan. This feedback loop helps keep ion levels steady and makes sure neutralization works well.

Tip: Clean emitter points often to keep ion output strong and keep ion balance. Make a cleaning plan to stop buildup and help your ionization system work well.

You must measure static charge very carefully to keep things safe. The electrostatic sensor from GD Decent Industry Co., Ltd. gives you good results every time. This sensor uses special charge induction and vibration capacitance technology. You do not have to touch the surface to check the charge. The sensor finds the electrostatic field and shows the voltage level. You can trust the results because the sensor has no moving parts. This helps it last longer.

Here is a table with the main features and technical details:

Feature/Specification | Description |

|---|---|

Non-contact measurement | Checks surface static voltage and electrostatic fields without touching. |

Detection technology | Uses charge induction and vibration capacitance technology. |

Component durability | Has no moving parts, so it does not wear out fast. |

Size and weight | Small and light, so it is easy to use. |

Power consumption | Uses little power, so it works efficiently. |

Sensitivity | Very sensitive, so it measures well in many jobs. |

Application | Works for factories and science research. |

You can use this sensor on assembly lines that work by themselves. It helps you find problems before they get worse. You can keep your workspace safe and stop damage to your products.

Note: Calibration is needed for correct charge measurement. You should follow rules like ANSI/ESD S20.20 and NASA-STD-8739.6. These rules help you get good results and keep your process working right.

You can use electrostatic sensors to watch for static charge in many jobs. This helps you stop mistakes that cost money. Sensors check charge levels and give you alerts right away. You do not have to stop work to test by hand.

Watching operator body voltage and metal tools keeps your workspace safe.

Real-time checks of ESD processes help you keep quality high.

IoT systems collect data by themselves, so you can do other work.

Fast alerts warn you about possible ESD problems.

Here are some common ways to use online electrostatic monitoring:

Application Area | Description |

|---|---|

Flow measurement of pneumatically conveyed solids | Good for checking how materials move in air systems. |

Measurement of particulate emissions | Used to watch and control emissions in many factories. |

Monitoring of fluidised beds | Helps keep fluidised bed systems working well. |

On-line particle sizing | Gives real-time data about particle sizes in different jobs. |

Burner flame monitoring | Makes sure burners work safely and burn well. |

Speed and radial vibration measurement | Checks machines for how well they work and when to fix them. |

Condition monitoring of power transmission belts | Checks belts to stop failures and downtime. |

Mechanical wear monitoring | Watches for wear in machines so you can fix them on time. |

Human activities monitoring | Used to check safety and how well people work at their jobs. |

You can make your process better and have less downtime with online monitoring. This keeps your production line working well and protects important parts from static charge.

You can use air ionization to control static electricity. This method uses high-voltage systems to make ionized air. The system sends out positive and negative ions. These ions move toward surfaces with opposite charges. When ions touch these surfaces, they balance the charge. This helps neutralize static electricity. You can change how much ionization you need.

Air ionizers like ionizing bars and ion fans help keep your workspace safe. These ionizers send ions that quickly remove static from insulators and other surfaces. Ionized air works well in places like electronics factories and clean rooms. The ions do not harm your products. They protect sensitive parts from electrostatic problems.

Tip: Check airflow, temperature, and humidity in your workspace. These things can affect how well your air ionizers work.

There are many types of esd air ionizers used in industry. Each type helps in different ways. Here is a table that shows the main types and their features:

Type of Ionizer | Best For | Key Features |

|---|---|---|

Benchtop Ionizers | Individual workstations handling sensitive components | Targeted protection, small footprint, covers 2-3 feet |

Overhead Ionizers | Production lines and larger work areas | Broader coverage, unobstructed workspace, multiple stations |

Ionizing Blow-Off Guns | Targeted static elimination on specific parts | Precision control, on-demand operation, cleaning parts |

Specialized Zero-Volt Ionizers | Ultra-sensitive applications requiring precise control | Extremely tight balance specifications, critical handling |

Point-of-Use/Nozzle-Style | Neutralizing static charges and dislodging dust | Hand-held or fixed, uses compressed air or nitrogen |

Workstation/Fan Ionizers | General workstation use | Various shapes and sizes, compact design |

You can use esd air ionizers to fix two big problems. First, ionizers stop electrostatic discharge that can hurt electronic circuits. Second, ionizers lower electrostatic attraction that causes dust in clean rooms. Ionization removes static charges from insulators in seconds. You will see less dust and dirt on your products.

Ionizers help keep your workspace clean.

Ionization lowers the risk of ESD damage.

Air ionizers help make your products better.

GD Decent Industry Co., Ltd. sells air ionizers and other helpful products. You can use their aluminum foil anti-static solutions and heat-resistant labels for extra safety. These products work well with ionizing bars and ion fans. You will get better static control and a safer place to work.

Static electricity can cause many problems on your production line. Electrostatic discharge can break sensitive parts. It can also erase data and even start fires. Here are some common problems you might see:

Electronic parts can break, so products do not work right.

You spend more money because you must throw away broken parts.

Important systems can lose or mess up data.

Short circuits and broken hardware can stop your work.

Fires or explosions can happen if there are flammable things nearby.

Electrostatic discharge can make medical devices like analyzers and pumps fail. These failures waste your time and money. You need a good plan to control static and keep your process working well.

GD Decent’s static control solutions help you lower these risks. You can follow these steps to make your process better:

Step | Description |

|---|---|

1 | Find where static comes from by doing a static survey. |

2 | Put in static dissipaters to make a strong control system. |

3 | Check again with a static survey to see if static is gone. |

4 | Keep checking static dissipaters and add static control to your change plans. |

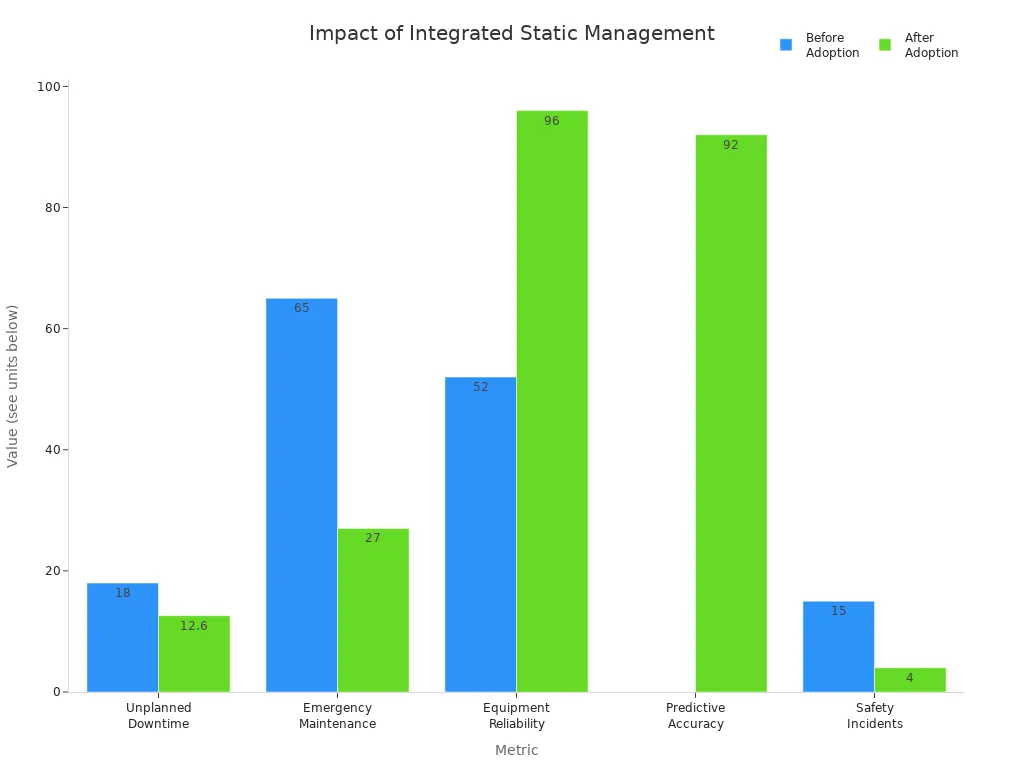

When you use ion fans and static sensors together, you have less downtime and fewer mistakes. The chart below shows how your process can get better:

You want your workplace to be safe and your products to be good. Ionization helps you reach these goals. When you control static, you lower the chance of fires and explosions. You also keep workers safe from shocks and sparks.

ESD materials with controlled static dissipation give more protection and reliability. They also help you follow safety rules. This is important in jobs where safety and accuracy matter a lot.

Here are some ways ionization and static control make things safer and better:

Stop fires by keeping sparks from lighting flammable things.

Lower hidden damage to electronics, so products stay good.

Make microchip failures less likely in electronics factories.

Keep medical devices safe and working right.

You should follow rules like ANSI/ESD S20.20 and IEC 61340-5-1. These rules help you keep your team and products safe. When you use ionization and static control tools from GD Decent, your process is safer and more reliable.

You can control static well by using electrostatic sensors and ion fans together. This helps keep your workspace safe and working smoothly. GD Decent’s solutions let you handle static fast and protect your products. Experts say you should follow these steps for the best results:

Be a good leader and make clear rules.

Make careful plans and teach your team.

Check how things work and look at results often.

Write down what happens and check your system.

Fix problems and stop them from happening again.

New ideas include smart sensors, IoT tools, and green designs. Using these together helps you stay safe and make better products every day.

An electrostatic sensor checks for static electricity on surfaces. It helps you find spots with lots of static charge. You can fix problems before they start.

Ion fans blow out ions that take away static charges. This keeps your workspace safe and free from dust. Clean rooms need this to keep products high quality.

ESD hazard happens when static discharge hurts sensitive parts. If you do not control static, you can lose time and money. Sensors and ion fans help you stay safe from these problems.

You can use electrostatic sensors with ionizing bars and anti-static mats. Special labels also help. These tools work together to keep your production line safe.