Introduction: Why Anti-Static Materials Matter

Ever touched a doorknob and felt a sudden spark?

That tiny shock might seem harmless, but in industrial settings, it can be costly — even dangerous.

Static electricity forms when two surfaces rub together and exchange electrons.

It hides on everyday items like plastic, rubber, and clothing.

In homes, it’s annoying. In factories, it can destroy electronics or ignite flammable materials.

Anti-static materials exist to stop that from happening.

They prevent static buildup before it becomes a problem.

By controlling how electricity moves across surfaces, they protect both people and equipment.

In industries like electronics, pharmaceuticals, and chemical storage, static control isn’t optional — it’s a necessity.

A single electrostatic discharge (ESD) can ruin sensitive chips or trigger explosions near fuel vapors.

To understand how big the risk is, consider this data:

| Industry | Risk Without Static Control | Common Damage |

|---|---|---|

| Electronics | High | Burnt microchips, data corruption |

| Chemicals | Very High | Ignition of flammable gases |

| Medical | Medium | Equipment malfunction |

| Packaging | Moderate | Dust contamination, product damage |

These issues cost companies millions every year.

That’s why anti-static materials have become essential in safe, modern manufacturing.

At Decent, we focus on creating high-quality anti-static materials — films, bags, and coatings — to prevent these risks.

They help factories stay safe, clean, and compliant with international safety standards.

Whether it’s protecting microchips, storing medicine, or wrapping powders, anti-static materials make every environment safer and more reliable.

What Is Anti-Static Material?

An anti-static material is a specially engineered substance that helps prevent the buildup of static electricity.

It doesn’t let electrical charges stay trapped on surfaces, keeping products, people, and machines safe.

Static electricity forms when two materials touch, separate, or rub together.

Electrons move from one surface to another, leaving a charge imbalance.

If that charge releases suddenly, it can damage sensitive electronics or even ignite flammable gases.

Anti-static materials work by spreading out those charges so they can safely dissipate into the air or ground.

They don’t conduct electricity as freely as metals, but they allow just enough movement to stop sudden discharges.

Common Types of Anti-Static Materials

| Type | What It’s Made Of | Typical Use |

|---|---|---|

| Anti-Static Plastic | Polypropylene, polyethylene, or PVC with additives | Electronic trays, packaging boxes |

| Anti-Static Coating | Conductive polymers or sprays | Work surfaces, industrial floors |

| Anti-Static Fabric | Polyester blended with carbon fibers | Cleanroom apparel, gloves, lab coats |

| Anti-Static Foam | Polyurethane or polyethylene | Protecting devices during shipping |

Key Properties

Surface Resistivity: Between 10⁵ and 10¹¹ ohms, which allows controlled charge dissipation.

Durability: Resistant to temperature changes and humidity.

Safety: Prevents static discharge that can cause fires or device failure.

Cleanliness: Reduces dust and contamination on surfaces.

In industries such as electronics manufacturing, medical devices, and chemical processing, static buildup can cause serious damage or downtime.

That’s why anti-static materials are essential — they balance electrical resistance, strength, and safety in one solution.

At Decent, our range of anti-static films, bags, and coatings are designed for these demanding environments.

They ensure static control while maintaining flexibility, clarity, and durability — the perfect blend for modern manufacturing.

Anti-Static vs Static Dissipative vs Conductive Materials

These three material types are all designed to manage static electricity, but they work in different ways.

Understanding their differences helps us choose the right one for each environment — from cleanrooms to chemical plants.

How They Differ

| Property | Anti-Static | Static Dissipative (ESD) | Conductive |

|---|---|---|---|

| Main Function | Prevents static buildup | Controls how charge flows | Transfers charge instantly |

| Resistance Range (Ohms) | 10⁵–10¹¹ | 10⁶–10⁹ | <10⁶ |

| Charge Movement Speed | Very slow | Controlled, moderate | Very fast |

| Risk Level | Low | Medium | High |

| Common Uses | Packaging, flooring, apparel | Electronics, aerospace, cleanrooms | Fuel handling, explosive zones |

1. Anti-Static Materials

These materials reduce static buildup on surfaces but don’t control how the charge moves.

They are often used for temporary protection — like in anti-static sprays, plastics, and carpets.

Typical Uses:

Plastic packaging and wrapping films

Anti-static flooring in offices or data centers

Protective gloves and apparel for workers

They’re great for preventing minor shocks or dust attraction but not suitable for ESD-sensitive environments such as semiconductor manufacturing or explosive areas

2. Static Dissipative (ESD) Materials

Static dissipative materials sit in the middle ground between anti-static and conductive.

They let charges flow slowly and safely to ground, avoiding sudden discharges.

Resistance range: 10⁶–10⁹ ohms

Used in electronics, cleanrooms, and manufacturing environments

Examples include ESD-safe plastics, coated flooring, and dissipative mats

Because they balance resistance and control, they’re ideal for protecting sensitive devices like circuit boards and microchips

3. Conductive Materials

Conductive materials allow electric charges to move instantly to ground.

Their resistance is extremely low, typically below 10⁶ ohms.

They’re essential in industries where explosive gases or powders are present — a single static spark could cause a fire.

Examples:

Conductive bulk bags (Type C FIBC) for powder handling

Carbon-filled polymers used in aerospace and automotive parts

These materials are tough, reliable, and built for high-risk environments

Choosing Between Them

Use anti-static materials for general safety and packaging.

Choose static dissipative for electronics, medical, and controlled environments.

Pick conductive materials when explosive or fuel-handling risks exist.

Each plays a unique role in static control — the right one keeps your operation safe, clean, and compliant with ESD standards.

Types of Anti-Static Packaging Materials (Decent Product Focus)

When products move through production or shipping, static electricity can silently damage them.

That’s why Decent designs a wide range of anti-static packaging materials — to keep sensitive items safe, clean, and static-free from start to finish.

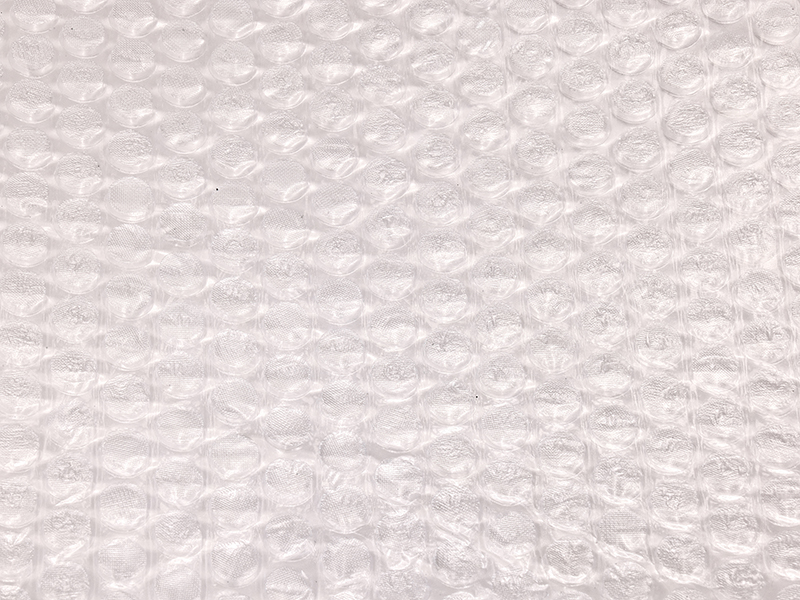

1. Anti-Static Bubble Wrap

This protective wrap combines cushioning and static control in one.

Unlike regular bubble wrap, it contains additives that prevent charge buildup on the surface.

Key Benefits:

Soft, flexible, and reusable

Prevents shocks and dust attraction

Perfect for fragile electronics, sensors, or optical lenses

Applications:

Used for wrapping electronic parts, delicate medical devices, and lightweight precision instruments.

| Feature | Benefit |

|---|---|

| Static Protection | Prevents charge accumulation during packing and shipping |

| Cushioning | Absorbs vibration and impact |

| Transparency | Easy product inspection |

Decent’s anti-static bubble wrap keeps your goods safe without leaving static residue on surfaces.

2. Anti-Static Poly Bags and Tubing

These bags are simple yet powerful tools for static protection.

They prevent charge buildup on both the product and the packaging.

Available Formats:

Open-Ended Bags: Easy to fill and seal

Reclosable Bags: Reusable zipper style for small components

Poly Tubing: Continuous rolls for adjustable bag lengths

Why Use Them:

Protects small parts, nuts, and electronic components

Keeps work areas clean by reducing dust and static

Lightweight, clear, and customizable

| Bag Type | Best For | Static Protection Level |

|---|---|---|

| Open-Ended | Bulk parts | Moderate |

| Reclosable | Reusable storage | Moderate to High |

| Poly Tubing | Long or irregular shapes | Moderate |

Decent’s poly bags and tubing are made from pink anti-static polymers that remain effective even in dry environments.

3. Anti-Static Foam Sheets and Inserts

Anti-static foam provides two levels of protection — cushioning and static control.

It’s ideal for products that are delicate and electrostatically sensitive.

Advantages:

Prevents charge buildup on both foam and product

Reduces shock damage during transport

Can be easily cut or shaped to fit custom packaging

Typical Uses:

Electronic parts, precision tools, and optical components

Inserts inside boxes or cases for protection

Specifications:

Available in multiple thicknesses (½”, 1”, 2”) and densities, depending on your protection level needs.

Decent supplies custom foam packaging for manufacturers who require long-term, anti-static cushioning solutions.

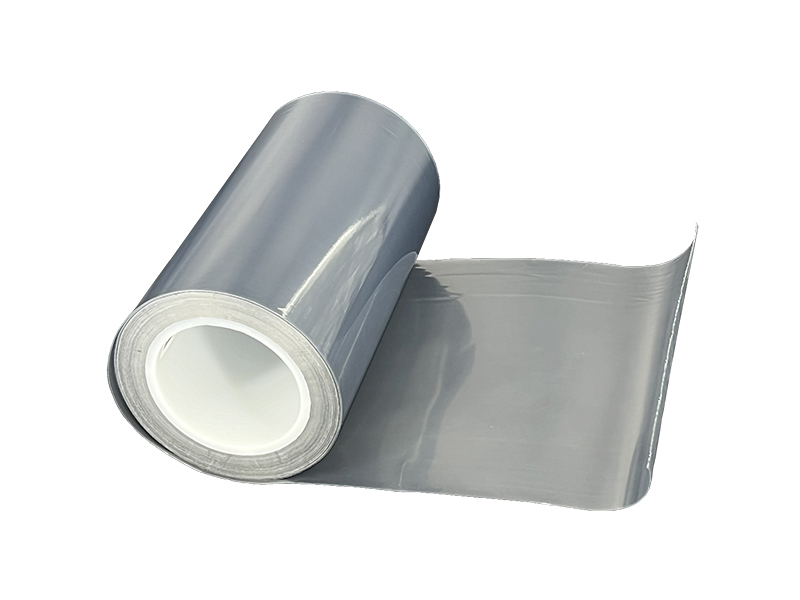

4. Anti-Static Packaging Films

Anti-static films act as a flexible barrier that protects items from both static and contamination.

They’re widely used for wrapping, sealing, and lining containers in sensitive production areas.

Benefits:

Transparent for product visibility

Compatible with automated wrapping machines

Reduces static charge during movement and storage

Applications:

Used in electronics, semiconductor, and medical manufacturing environments.

Decent’s anti-static PE films are available in rolls and custom-cut formats, ensuring a perfect fit for any industrial workflow.

5. Anti-Static Foam Rolls (For Surface Protection)

These rolls cover large areas or line containers during transport.

They prevent charge buildup on surfaces and protect components from scratching.

Ideal For:

Pallet layers and surface liners

Transporting polished or coated materials

Decent’s foam rolls come pre-perforated for easy tearing, making them practical for both manual and automated packaging setups.

Comparison Chart: Decent’s Core Anti-Static Packaging Solutions

| Packaging Material | Function | Main Benefit | Reusable | Applications |

|---|---|---|---|---|

| Bubble Wrap | Cushioning + Static Control | Shock & charge protection | Yes | Fragile electronics |

| Poly Bags / Tubing | Static Prevention | Lightweight protection | Yes | Small components |

| Foam Sheets | Cushioning + Static Dissipation | Custom-fit inserts | Yes | Precision instruments |

| Films | Wrapping + ESD Control | Transparent barrier | Yes | Electronics, cleanrooms |

| Foam Rolls | Surface Protection | Prevents abrasion & static | Yes | Pallet layers, containers |

FAQs About Anti-Static Materials

People often have questions about how anti-static materials work and where they differ from ESD or conductive types.

Below are the most common questions we get at Decent, explained in clear and simple terms.

1. What materials do not cause static electricity?

Materials that let electricity flow easily don’t create static buildup.

Metals like copper, aluminum, and steel allow electric charges to move freely.

Some carbon-infused plastics and static dissipative polymers also help prevent static by slowly releasing charge into the air

2. Are ESD and anti-static materials the same?

No — they’re not identical.

Anti-static materials prevent static buildup but don’t control how charges dissipate.

ESD (electrostatic dissipative) materials regulate how charge flows to ground, stopping sudden electrostatic discharge (ESD).

Choosing the correct type is crucial when protecting microchips, circuit boards, or flammable materials

3. What’s the difference between static dissipative and conductive materials?

| Property | Static Dissipative | Conductive |

|---|---|---|

| Resistance Range (Ω) | 10⁶–10⁹ | <10⁶ |

| Charge Flow | Controlled, slow | Instant discharge |

| Best For | Electronics assembly, cleanrooms | Explosive or fuel-handling areas |

Static dissipative materials release charge gradually.

Conductive materials transfer charge instantly — ideal when fast grounding is required

4. How do I test if a material is ESD safe?

Testing is simple.

Use a surface resistance meter or ohmmeter to check resistivity.

ESD-safe materials usually fall between 10⁶ and 10⁹ ohms.

You can also confirm compliance with ANSI/ESD S20.20 or EN 61340-5-1 standards

5. What is anti-static packaging used for?

Anti-static packaging stops static buildup that might harm products.

It’s pink in color and used for items not overly sensitive to ESD but still used in static-sensitive environments.

While it won’t block static discharge like shielding bags, it prevents charge generation during handling and transport

6. How long do anti-static materials last?

Their performance can weaken with time or reuse.

Exposure to dust, moisture, or friction may reduce effectiveness.

Before reusing anti-static packaging, always inspect for wear or surface changes

7. What types of packaging have anti-static properties?

Several packaging options include built-in anti-static protection:

Bubble wrap: Cushions and controls static buildup

Poly bags and tubing: Great for small parts

Foam sheets: Provide both cushioning and static control

Foam rolls: Protect surfaces and prevent abrasion